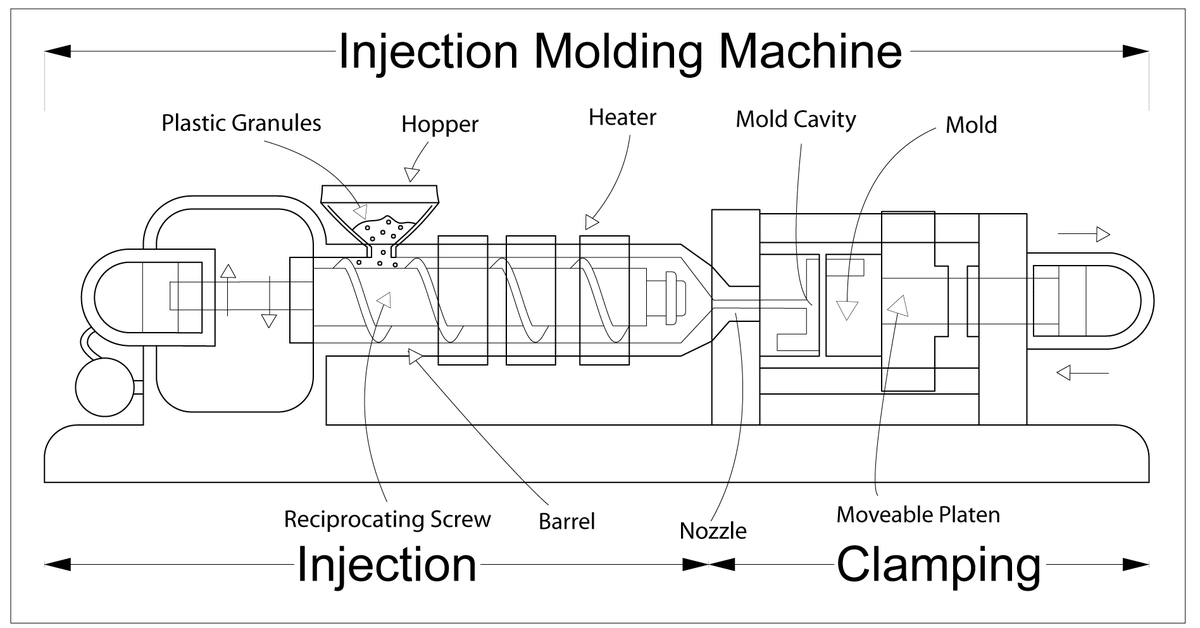

The definition of injection molding is as a method of production objects which is done by the use of an injection molding machine with a heat-meltable plastic material. The shape of products is controlled by a confined chamber called a mold.

The injection molding process is one of the most versatile production methods in the plastic manufacturing industry. It is a major processing technique for converting thermoplastics or thermoset plastics into variety types of products for different end uses such as space shuttle to automotive, electronic to medical, sports to recreation, building and construction to machine, consumer products to medical apparatus and instruments.

Both product design and processing of the material are two important steps designing a plastic part. Several factors must be considered, the most important one is workpiece design. Other factors such as the economics, quality, appearance, and performance of the plastic workpiece also need to be considered. All of these factors must be considered in determining the feasibility if manufacturing a plastic workpiece.

Just as we have discussed that injection molding process involves feeding pellet material melting this pellet material from solid to molten plastic material, and forcing this melt through a barrel by a screw, conveying this molten material from the barrel through sprue, runner and gates into cavities of mold, and then cooling and forming this melt inside the mold which may also have such features as cores, inserts, and cavities.

There are several considerations in selecting the right material before object design: service temperature, chemical environment, workpiece economics and product specifications.

About JasonMould Industrial Company Limited

Jasonmould is a manufacturer of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer- plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.

Contact:

Person: James Yuan

Company: JasonMould Industrial Company Limited

Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Tel: 86-752-6682869

Email: james@jasonmolding.com

Person: James Yuan

Company: JasonMould Industrial Company Limited

Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Tel: 86-752-6682869

Email: james@jasonmolding.com

Article Original From:https://www.jasonmolding.com/workpiece-design-for-injection-molding/